Choosing WOOD ELEMENTS exterior cladding for your home adds a warmth and timeless charm. Creating a connection to the natural environment and a living space for you to enjoy and relax in.

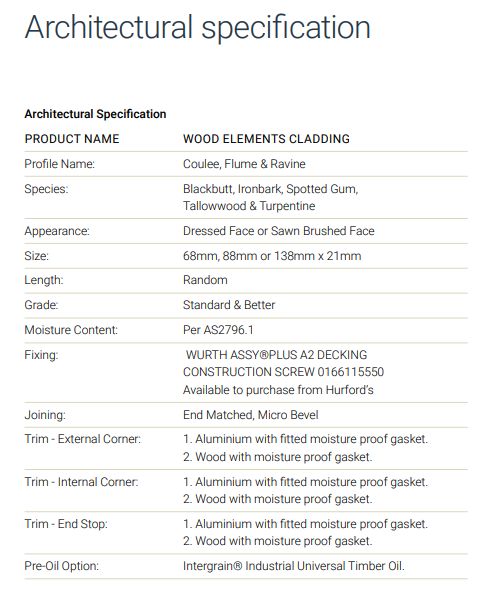

You have the option to select from three designer profiles all with their own unique look and in a range of Australian hardwood species. Only the highest quality and naturally durable Australian hardwood species have been selected to produce WOOD ELEMENTS. Rated Durability Class 1 under the Australian Standard AS 5604 -2005, these species provide the best result for lasting performance.

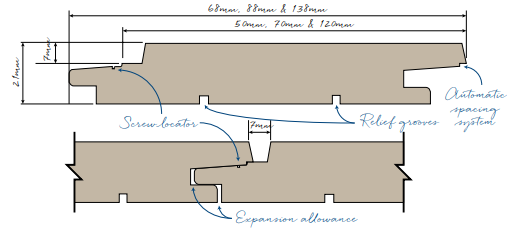

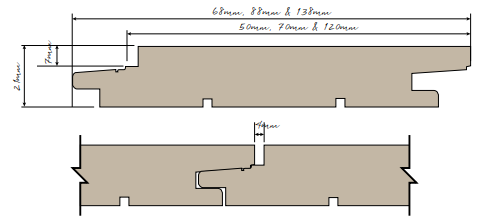

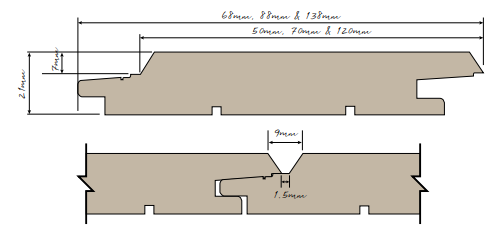

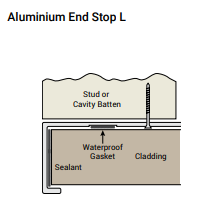

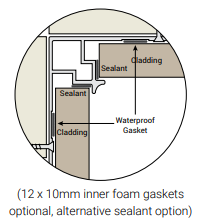

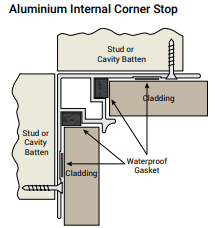

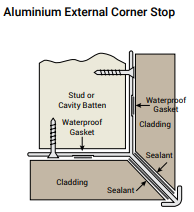

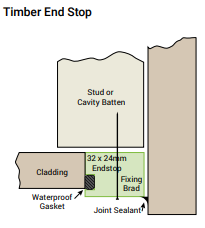

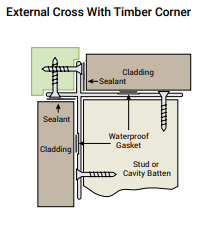

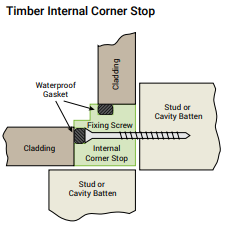

WOOD ELEMENTS complete system is the perfect choice for easy installation with its end matching, concealed screw fix, automatic spacing design, exclusive designer trims and Australian hardwood backed by Hurford’s expertise in drying and machining ensuring a precision result.