The strongest pine glulam beam available

Hyne Beam 17 is the strongest softwood glue laminated beam available, with numerous structural applications, particularly where high load and critical performance is required.

The renowned natural strength of timber is enhanced with our glue laminating process, ensuring Beam 17 is lightweight and ideal for long span / high load applications.

Builders know how practical Hyne Beam 17 is for lintels over large window and door openings and for garage beams, or as roof beams where spans over large spaces are dictated by design. Readily available, in the commonly used range of sizes and lengths, they are much easier to install than steel.

Beam 17 is produced from renewable resources protecting our environment for future generations.

Application

Main Product Application

> Roof beams, bearers, columns, floor joists, rafters, lintels, portal frames

Size, grades and tolerance

Lengths >

2.4 to 15.6 m in 0.3m increments

Size range (mm) >

| Thickness | Depth |

| 65 | 65 130, 165,195, 230, 260, 295, 330, 360, 395, 425, 460,495 |

| 85 | 85 130, 165,195, 230, 260, 295, 330, 360, 395, 425, 460,495, 525, 560, 590 |

| 130 | 135 130, 165,195, 230, 260, 295, 330, 360, 395, 425, 460,495, 525, 560, 590 |

Tolerance on Section >

| Depth | Tolerance |

| <50mm | ± 0mm |

| <100mm | ± 1mm |

| <150mm | ± 2mm |

| <300mm | ± 3mm |

| <450mm | ± 4mm |

| <600mm | ± 5mm |

| <601mm | ± 6mm |

Thickness – 2mm

Grades

Hynebeam 17 is available as A Appearance and C Structural Grade (STR) as defined in AS1328.1.

Select Grade specified as (SEL)

This beam is equivalent to appearance Grade A: AS 1328.1 – 1998. This grade is intended for use in applications where appearance of the member is important and clear or painted finishes are used. All surface voids are therefore filled or repaired. Unless otherwise specified, the surfaces are sanded to a minimum 60 grit finish.

Structural Grade specified as (STR)

This beam is equivalent to appearance grade C: AS 1328.1 – 1998. This grade is intended for use in applications where appearance is not important. All blemishes and voids are acceptable.

Product information:

Species specification

The species used consists of machine graded Pinus elliottii, Pinus caribaea, Hybrids of these and Pinus radiata.

Adhesive specification

Resorcinol based glues (PRF – Phenol Resorcinol Formaldehyde) are used which are suitable for Service Class 3.

Moisture content

Basic definition

Moisture content is the mass of moisture present in wood divided by the mass of the wood with no moisture in it, expressed as a percentage.

Moisture content range

The moisture content of Hynebeams has a range of between 8-15%. The moisture content is uncorrected. Therefore moisture meters used to confirm the moisture content need be set to Douglas-fir and 20ºC which are the default setting for most moisture meters.

Treatment and Durability:

Treatment options

Available untreated or H3 treated in accordance with the requirements of AS/NZS 1604.5.

Natural durability, lyctid susceptibility of sapwood and termite resistance of heartwood

| Species | Lyctid susceptibility of sapwood | Natural Durability class of heartwood | Termite Resistance of Heartwood | |

| In-ground contact | Outside above ground | |||

| Radiata Pine (Pinus radiata) | Not susceptible | 4 | 4 | Not Resistant |

| Slash Pine (Pinus eliottii), Caribbean Pine (Pinus caribaea) | Not susceptible | 4 | 4 | Resistant |

In-ground contact – Class 4

Source: AS 5604-2005 (Incorporating Amendment No. 1) Timber-Natural durability ratings

Maintenance

Please refer to Hyne Technical Data Sheets In weather exposed applications (TDS6), Sealing, painting or varnishing (TDS8) and Hyne ETP Design for Durability (TDS9).

Service Classes

Service Class 1 – Service Class characterized by a moisture content in the materials corresponding to a temperature of 20ºC and relative humidity of the surrounding air only exceeding 65% for a few weeks per year.

Note: On Service Class 1 the average equilibrium moisture content in most glulam will not exceed 12%.

Service Class 2 – Service Class characterized by a moisture content in the materials corresponding to a temperature of 20ºC and relative humidity of the surrounding air only exceeding 85% for a few weeks per year.

Note: On Service Class 2 the average equilibrium moisture content in most glulam will not exceed 20%.

Service Class 3 – Service Class characterized by climatic conditions leading to higher moisture contents than Service Class 2, or where timber is directly exposed to sun and/or rain.

Note: Refer to additional technical Information sheet.

Source: AS/NZS1328.1 – 1998 Glued laminated structural timber – Performance requirements and minimum production requirements

Design information:

Design properties

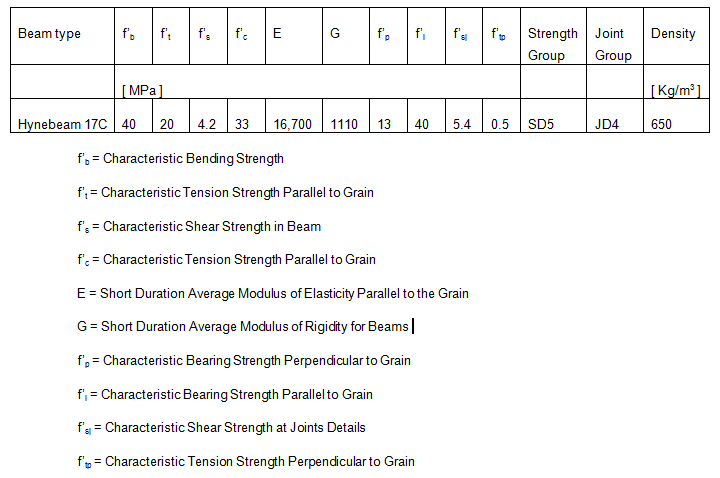

Mechanical properties have been determined in limit state format form with a comprehensive testing and evaluation program carried out by Hyne. The modulus of rigidity is calculated by using G = E/15. Density is a measured property and is determined as average seasoned density. However properties such as Bearing Strength Perpendicular to Grain, Bearing Strength Parallel to Grain, Shear Strength at Joints Details and Tension Strength Perpendicular to Grain are secondary properties which are depending on the strength group for the material and are determined in accordance with AS1720.1-2010. Further joint group are based on the material used and the groups are defined based on species and density as per AS1720.1-2010.

Characteristic properties for Hynebeam 17C

Values of capacity factor (F) for calculating the design capacity of (F Rd) of structural members

| Structural Material | Application of structural member | ||

| Structural members for house for which failure would be unlikely to affect an area* greater than 25 m2; | |||

OR

secondary members in structures other than housesPrimary structural elements in structures other than houses

OR

elements in houses for which failure would be likely to affect an area* greater than 25m2Primary structural members in structures intended to fulfil an essential service or post disaster functionValues of capacity factor, FGlue-laminated timber-AS/NZS 1328 10.950.850.75

* In this context, area should be taken as the plan area.

Source: AS1720.1 – 2010 Timber Structures Part 1: Design methods

Duration of load factor (j2) for creep deformation:

| Load Duration | Service Class/Exposure Classification | ||

| 1 & 2 | 3 | Severe/Adverse | |

| Short Term ? 1 day | 1.0 | 1.0 | 1.0 |

| Long Term ? 1 year:Section width > 45mm | 1.5 | 2.0 | 3.0* |

| Long Term ? 1 year:Section width ? 45mm | 2.0 | 2.0 | 3.0* |

Source: GLTAA Technical Data Sheet No. 3 Unified Design Criteria.

The engineering design data presented may be used for structural design of domestic, commercial and industrial applications in conjunction with:

- AS1684.1 – 1999 Residential timber-framed construction Part 1 Design Criteria

- AS1720.1 2010 – Timber Structures Part 1: Design methods

- GLTAA (Glued Laminated Timber Associated of Australia) Uniform Design Criteria,

and all other relevant standards (e.g. loading codes, wind codes, etc.).

Conductivity and Resistivity

Conductivity k

For moisture contents below 25%, approximate thermal conductivity k across the grain can be calculated with a linear equation of the form

K = Gx(B + CX) + A

where Gx is specific gravity based on ovendry mass and volume at moisture content x (%) and A, B, and C are constants.

For Gx> 0.3, temperatures around 24 ºC, and x < 25% MC, the values of the constants are as follows:

A = 0.01864, B = 0.1941, C = 0.004064 (kin W m-1 K-1)

GX = 0.65

Thermal conductivity of Slash Pine:

| Species | Specific gravity | Conductivity (W m-1K-1) | Resistivity (K m W-1) | ||

| Ovendry | 12% MC | Ovendry | 12% MC | ||

| Slash | 0.61 | 0.14 | 0.17 | 7.3 | 6.0 |

Source: Centennial Edition Wood Handbook Wood as an Engineering Material, Forest Product Laboratory, United States Department of Agriculture Forest Services, Madison Wisconsin, 2010.

Camber

Hynebeams with “C” designates a Hynebeam with a vertical camber radius of curvature of 600mm. “S” designates a straight Hynebeam. Alignment Tolerance of both straight and cambered beams shall be no more than 1mm per metre of length of beam.

Hynebeams are generally supplied as cambered marked to identify the top edge of the beam. Unless specifically requested (such as for large cantilevers), this brand should not be installed facing downwards. The below table displays the amount of camber versus beam length.

| Beam length (m) | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 3.9 | 4.2 | 4.5 | 4.8 | 5.1 | 5.4 |

| Camber (mm) | 1.2 | 1.5 | 1.9 | 2.3 | 2.7 | 3.2 | 3.7 | 4.2 | 4.8 | 5.4 | 6.1 |

| Beam length (m) | 5.7 | 6.0 | 6.3 | 6.6 | 6.9 | 7.2 | 7.5 | 7.8 | 8.1 | 8.4 | 8.7 |

| Camber (mm) | 6.8 | 7.5 | 8.3 | 9.1 | 9.9 | 10.8 | 11.7 | 12.7 | 13.7 | 14.7 | 15.8 |

| Beam length (m) | 9.0 | 9.3 | 9.6 | 9.9 | 10.2 | 10.5 | 10.8 | 11.1 | 11.4 | 11.7 | 12.0 |

| Camber (mm) | 16.9 | 19.0 | 19.2 | 20.4 | 21.7 | 23.0 | 24.3 | 25.7 | 27.1 | 28.5 | 30.0 |

| Beam length (m) | 12.3 | 12.6 | 12.9 | 13.2 | 13.5 | 13.8 | 14.1 | 14.4 | 14.7 | 15.0 | 15.3 |

| Camber (mm) | 31.5 | 33.1 | 34.7 | 36.3 | 38.0 | 39.7 | 41.4 | 43.2 | 45.0 | 46.9 | 48.8 |

| Beam length (m) | 15.6 | 15.9 | 16.2 | 16.5 | 16.8 | 17.1 | 17.4 | 17.7 | 18.0 | 18.3 | 18.6 |

| Camber (mm) | 50.7 | 52.7 | 54.7 | 56.7 | 58.8 | 60.9 | 63.1 | 65.3 | 67.5 | 69.8 | 72.0 |

Hynebeams 17 has a lamination thickness of 33mm.

Standards:

Manufacturing standards:

TAS/NZS 1328.1 – 1998 Glued laminated structural timber Part 1: Performance requirements and minimum production requirements

AS 5068 – 2006 Timber – Finger joints in structural products – Production requirements

Design Standards:

AS1684.1-1999 Residential timber-framed construction – Design criteria

AS1720.1-2010 – Timber structures Part 1: Design methods

Third Party Information:

Hyne Glulam Maryborough has an accredited Quality assurance in place meeting ISO 9001.

Click below to find out more or contact us on: John Carroll 0414301515 and Colin Carroll 0421273887

Email for a price or more information: John@carrollswholesale.com, Colin@carrollswholesale.com

Leave a Reply

Want to join the discussion?Feel free to contribute!