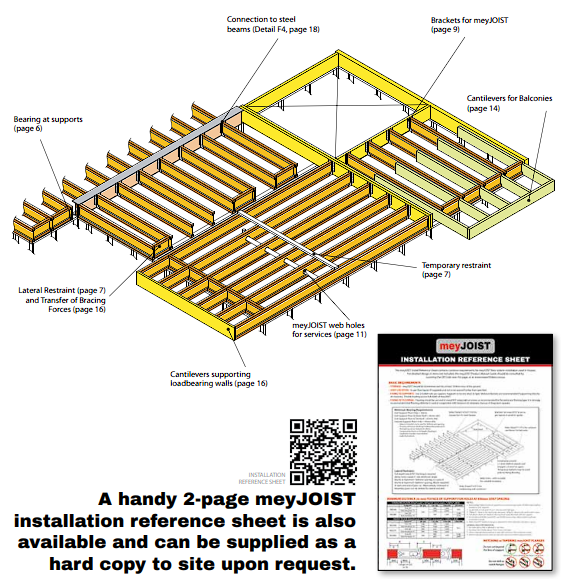

There are some aspects of both specification and installation that can be regarded by designers and builders as basic requirements. These should be adopted for installation in the absence of other or additional requirements that may be specified in the design documentation. Requirements that fit into this category are defined and detailed in this section called ‘General Requirements’.

Other aspects are categorised as ‘Installation details requiring design and specification’ (pages 14-17) because they need selection and individual specification in the design documentation to ensure the design intent is communicated to the builder.

This product manual provides a variety of details specific to the use of meyJOIST floor systems for houses and similar buildings. Details contained in this publication have been appropriately engineer designed and/or tested to determine their suitability. In addition, many details in AS1684 and other industry publications are equally applicable to meyJOIST as for conventional timber joisted floors. We do however, caution against any assumption that details published for other I-Joist products are suitable or sufficiently complete for use with meyJOIST.

Storage

Prior to installation, meyJOIST should be stacked on level bearers, at least 150mm clear of the ground and kept dry.

Joist Layout

In all cases it is assumed that installation will be carried out in accordance with a joist layout drawing showing the location, size (section code) and maximum spacings of joists, together with reference to any special requirements not included in this guide as ‘general requirements’.

Joist Placement

Joists should be accurately placed at not more than the nominated maximum centre to centre spacing so as to provide the support required for flooring and load bearing walls or posts. Joist placement must be so as to clear any obstructions that may occur through the floor such as plumbing, drainage pipes or air conditioning ductwork.

Fixing to Supports

Joists are to be fixed accurately in position at supports using nails or screws as per Detail F5. Nail through flanges using a minimum of 2/3.06Ø x 75mm long nails at least 40mm from the end of the joist. Screws up to 14g (6.3mm) x 75mm long can also be used for fixing to supports. When using screws it is strongly recommended to pre-drill the hole with a drill bit equivalent to the size of the screw shank to preventsplitting. See also‘Supports’section in this manual for further information.

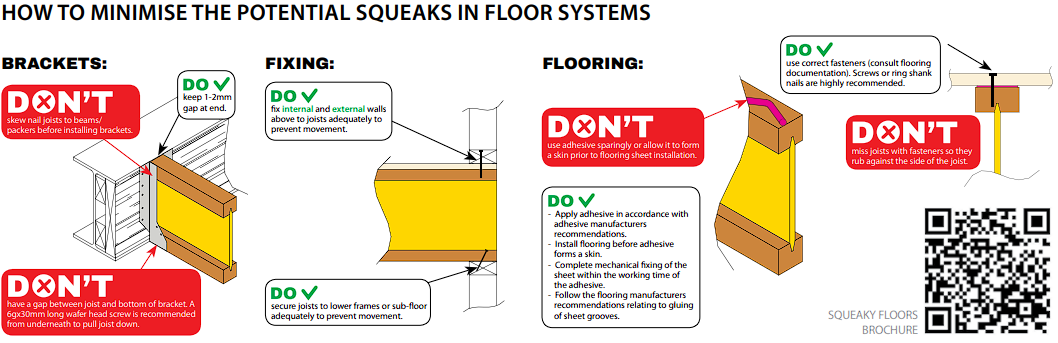

Fixing of SHEET Flooring

It is recommended that sheet flooring be secured to joists using self-drilling Type 17 screws or ring/twist shank nails. Nails should be minimum 2.8mm diameter nails, hand driven or minimum 2.5mm diameter nails, machine driven. Nail or screw spacing should be at centres recommended for the particular flooring type. Where nail centres are less than 50mm it is good practice to stagger their location so as to avoid the possibility of splitting. Flooring adhesive must used in conjunction with fasteners to minimize any chance of long term floor squeak.